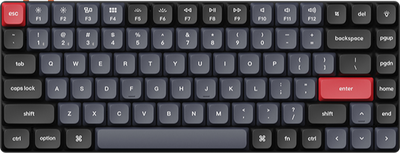

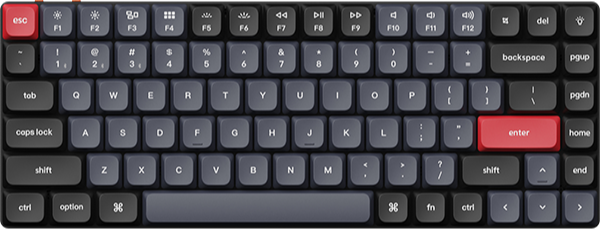

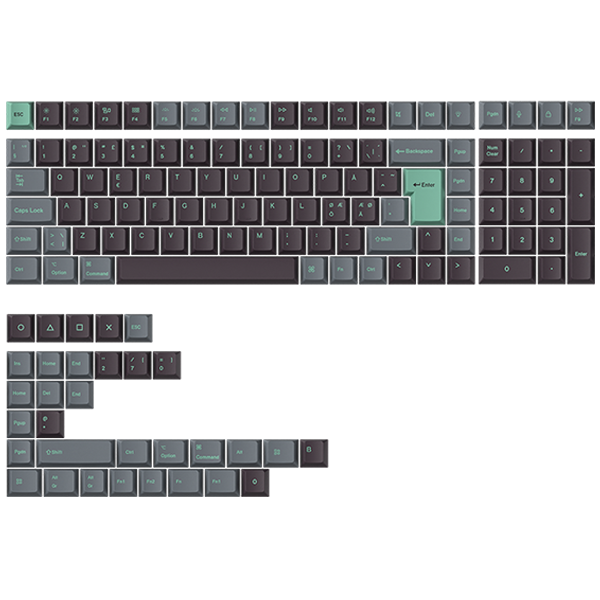

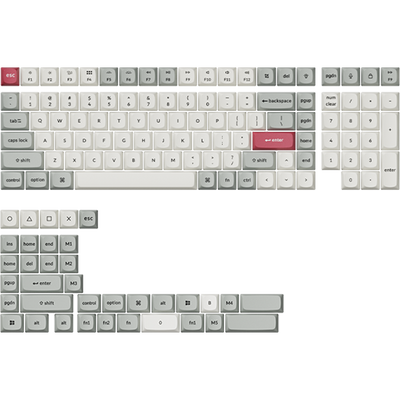

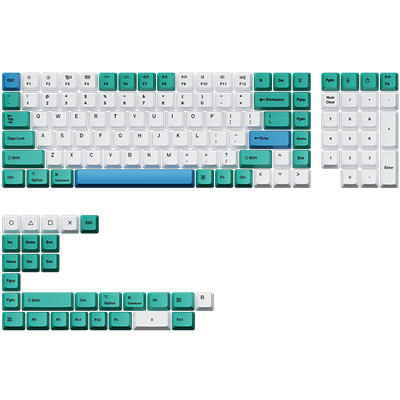

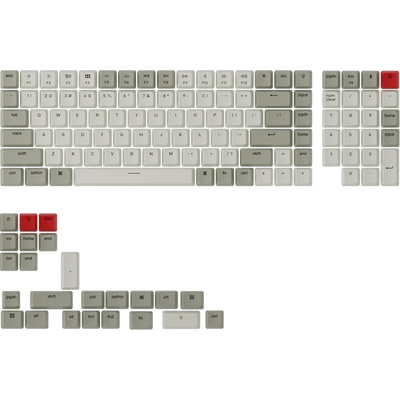

The lure of a fully customizable mechanical keyboard is obvious in an era where time at the keyboard often trumps time anywhere else. Keychron Q1, the QMK compatible and customizable keyboard, has entered the tray with the premium features, build quality and structure design. Today we are going to dive into the whole design of Keychron Q1.

How we create the Keychron Q1 customizable mechanical keyboard?

The lure of a fully customizable mechanical keyboard is obvious in an era where time at the keyboard often trumps time anywhere else. Keychron Q1, the QMK compatible and customizable keyboard, has entered the tray with the premium features, build quality and structure design. Today we are going to dive into the whole design of Keychron Q1.

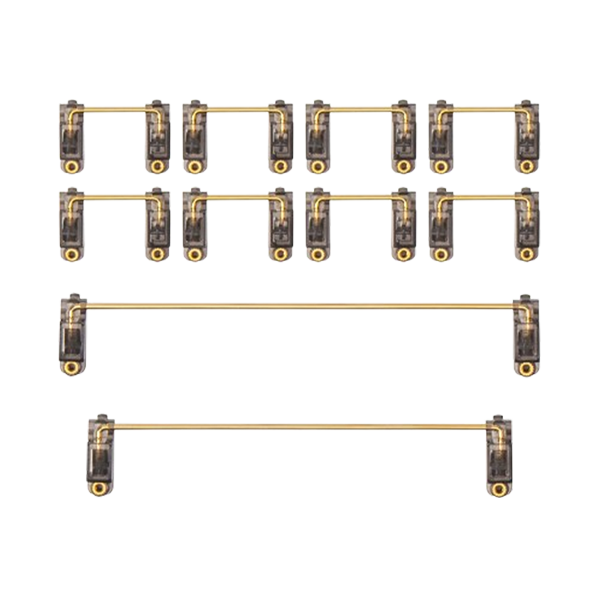

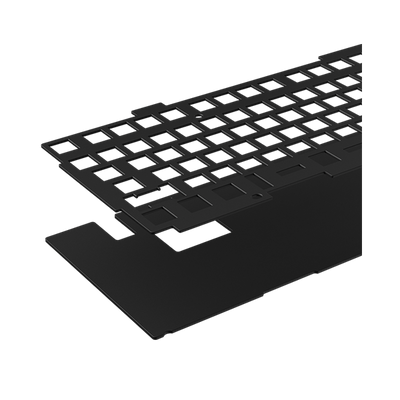

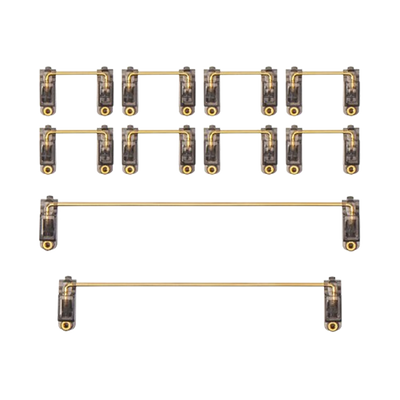

Gasket Mount Design

The internal makeup of a keyboard will affect the overall typing experience. This time, we incorporated the gasket mount design to the Keychron Q1. In short, the gasket mount uses a poron gasket to isolate the plate and PCB from direct contact with the case, giving a softer and quieter sound and feel.

With gasket mount design, Q1 mechanical keyboard offers you not only flexibility, but also a softer feel and bottom out on every fingertip touch. It has some noise isolation benefits as well since the design changes the way a board feels and sounds while typing.

One thing should be emphasized is that selecting different keyboard plates will bring different typing feel since the flexibility and softness of a mechanical keyboard, to a great extent, are related to the keyboard plate materials.

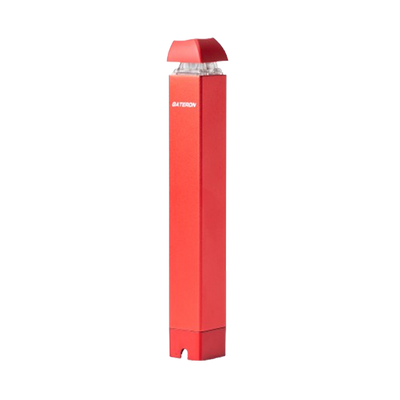

6063 Aluminum Body

Dedicated to creating the superior custom mechanical keyboard, the Q1 keyboard body is made of 6063 aluminum, which is widely recognized for its weldability and incredible durability, and ability to resist corrosion. Crafted with refined anodized matte surface, the smooth and shiny aluminum surface on the Q1 keyboard body makes typing as artful as it gets.

Manufacture Process

When manufacturing the keyboard, the CNC machining, sandblasting, polishing, and anodizing process are all incorporated at crucial stages to craft this premium keyboard. The accuracy of the CNC machine ensures consistent product quality and also enables the Q1 keyboard production of high precision. Regarding sandblasting and polishing, sandblasting can remove paint, rust and residue from metal surface quickly and efficiently while polishing enhances the appearance and creates a reflective surface of the Q1 keyboard.

We have also applied the anodizing process to the Keychron Q1, the purpose of which is to form a layer of aluminum oxide that will protect the aluminum beneath it. Thanks to the process, the aluminum on the Q1 keyboard retains its appearance for long periods of time.

Therefore, each Q1 keyboard is made to withstand scratches, corrosion, durability, as well as maintain its aesthetic appeal.