How To Build Your Own Mechanical Switch

Creating your own mechanical switch can be geeky but a very special and dedicated typing experience. It is exciting and amazing. To make the process as simple and perfect as possible, we'll cover everything you need to get started, pick the components and tools, and the practical steps to assemble everything.

Step 1: Decide What Switch You Want

There are different types of mechanical switches on the market. In terms of profile, it is available in Normal Profile and Low Profile. There are generally linear, tactile, and clicky in terms of feel. In terms of mounted style, there are 3-Pin and 5-Pin switches. In terms of SMD-LED compatibility, it includes Plug-in Switch and SMD Switch. First, we have to figure out what switch we want.

If you don't know what you want, a chosen switch will make this step much easier. It is recommended to purchase a switch tester to find out what typing experience you want.

Step 2: Pick Out the Components

| Components Required | The Option |

|---|---|

| Stem | Regular MX-style, box-style |

| Top Case | PC, Nylon, POM |

| Bottom Case | PC, Nylon, POM |

| Spring | Gold-plated, black-plated, stainless steel |

There are some main components required to build a switch. Picking out the right components is super important and you want to make sure they are all compatible with each other.

Here are the components that you’ll need:

Stem

The stem is a vertical plunger and is designed to provide feedback and actuate the switch by pressing the contact leaf. A stem comes in multiple shapes and sizes depending on the type of switch that houses it. Currently, regular MX-style stem and box-style stem are standard on the market. In many switches, the stem will bottom out on the slider rails. Due to their different sizes, the bottom-out feel they produce will also vary.

From L to R: Gateron G Pro Brown regular MX-style stem, Keychron K Pro Brown box-style stem, Kailh Box Brown box-style stem

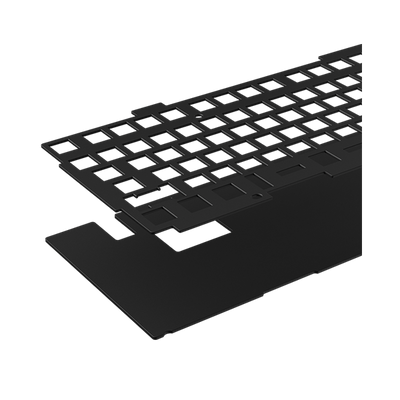

Top Case

There are a pair of slide rails on each side of the top case to keep the stem from being ejected too far. The material of the top case can determine how the switch sounds and feels when it returns and top-out, while also affecting the backlight effect of the switch. Usually, transparent PC covers have better light transmission than nylon covers.

L: Transparent PC cover

R: Milky nylon cover

Bottom Case

The bottom case contains metal contact leaves, slider rails, hollow legs for stem poles that may be called "center mast" or "stem holes", and switch pins for fixing switches to plates or PCBs. The layout of the bottom case generally affects switch compatibility.

Keychron Camo Switch Light Green Bottom Case

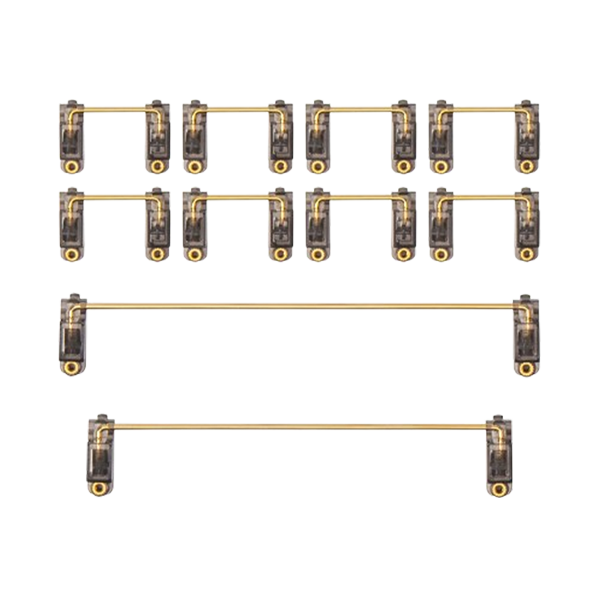

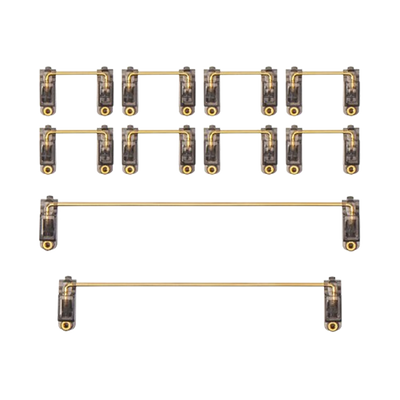

Spring

The spring allows the switch to slide and reset. Spring weight plays a big role in feeling and feedback. Different spring length led to different bottom out weight. There are many springs with different properties and sizes on the market, such as single-stage springs, multi-stage springs, Kailh Box springs, etc. When choosing, we should consider it comprehensively to ensure that it can be compatible with other components and suitable for our own feelings.

Spring from L to R: Gateron G Pro Red stainless steel spring, Gateron Kangaroo-63 gf black-plated spring, Kailh Box V2 Brown gold-plated spring, Keychron gold-plated spring, Gateron Baby Kangaroo 2-stage spring

Components Recommendations

Step 3:Lube the Components (Optional)

If you want to lube your switch, lube it before assembly is a good time to reduce the tedious step of opening the switch. You can apply lubricant to the top case, stem, spring, and bottom case. The whole process can take a few hours in the case of a higher number of switches, but it's a huge improvement in the feel of the switch, which reduces the spring noise and internal scratchiness, allowing for smoother keystrokes and better sound.

Be careful to avoid lubing clicky switches, as they can eliminate click sounds and make each switch sound uneven.

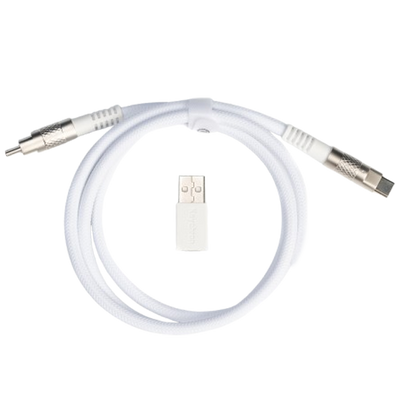

Tools for lubing switches

Step 4:Assemble the switch

Please watch the video above to see how to assemble a switch.